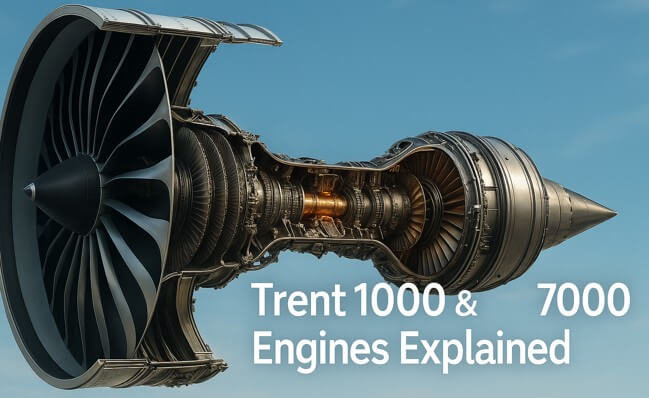

Trent 1000 Engine: Powering the Future of Aviation

The Trent 1000 engine is one of Rolls-Royce’s most significant achievements in the field of modern turbofan technology. Designed primarily for the Boeing 787 Dreamliner, it represents decades of expertise in three-spool engine design and showcases the continuing evolution of the Trent family. This article explores the development, design, performance, challenges, and future outlook of the Trent 1000 engine, while also examining its close relative, the Trent 7000 engine, which powers the Airbus A330neo. Together, these engines highlight Rolls-Royce’s strategy of advancing fuel efficiency, reducing emissions, and improving reliability for airlines worldwide.

The Trent Family Heritage

The Trent series began in the early 1990s and has since become a cornerstone of wide-body aircraft propulsion. Each generation builds upon the proven three-shaft design philosophy: a low-pressure system, intermediate-pressure system, and high-pressure system working together for maximum efficiency. The Trent 1000 was introduced in the early 2000s to compete directly with General Electric’s GEnx for the Boeing 787 programme, while the Trent 7000 was later created to serve the Airbus A330neo market.

Design Philosophy of the Trent 1000

The Trent 1000 engine features a large fan with a diameter of around 2.85 metres, advanced wide-chord fan blades, and a high bypass ratio exceeding 10:1. These elements allow the engine to deliver both high thrust and low fuel consumption. With thrust ratings ranging from 62,000 to 81,000 pounds, it covers the entire Boeing 787 family, from the smaller 787-8 to the long-range 787-10.

The three-shaft layout provides distinct advantages. By separating the compression stages into three rotating spools, Rolls-Royce achieves greater efficiency and optimises performance at different speeds. This design also reduces overall engine weight compared with a two-shaft configuration.

Environmental Performance

Airlines and regulators demand cleaner, quieter, and more sustainable engines. The Trent 1000 engine meets ICAO’s stringent Chapter 4 noise standards and demonstrates significantly reduced nitrogen oxide (NOx) emissions compared with earlier generations. The high bypass ratio not only boosts efficiency but also lowers external noise, improving passenger comfort and reducing environmental impact for communities near airports.

Operational Challenges and Solutions

No modern engine programme is without difficulties, and the Trent 1000’s service entry highlighted areas requiring attention. Early versions, known as Package A and Package B, encountered durability concerns, especially with intermediate-pressure compressor blades. Later, Package C and even early TEN (Total Engine care eNhanced) variants experienced premature wear in turbine components.

These issues led to increased maintenance visits and regulatory airworthiness directives. Airlines were occasionally forced to ground aircraft while waiting for replacement engines. Rolls-Royce responded with significant engineering redesigns, introducing durability improvement packages that extended on-wing life. Today, the majority of engines in service have benefitted from these upgrades, restoring operator confidence.

The Trent 1000 TEN: Next Evolution

The Trent 1000 TEN was launched to address earlier challenges and enhance long-term performance. It incorporates materials and technologies proven on other Trent family members, such as the Trent XWB powering the Airbus A350. By improving high-pressure turbine durability and enhancing efficiency, the TEN now represents the backbone of Rolls-Royce’s 787 offering. Its service record has steadily improved, with airlines reporting greater reliability and reduced maintenance burden.

Comparison with the GEnx Engine

On the Boeing 787, airlines may choose between the Rolls-Royce Trent 1000 and General Electric’s GEnx-1B. Both engines target similar performance goals, but their design philosophies differ. The Trent’s three-shaft system contrasts with GE’s two-shaft approach. Rolls-Royce emphasises time-on-wing and fuel efficiency improvements over the long term, while GE has historically promoted initial reliability advantages. Over time, competition between the two has driven innovation, ultimately benefitting airlines with lower operating costs and enhanced performance.

Economic Impact for Airlines

Fuel represents one of the largest expenses for airlines, and the Trent 1000 engine plays a crucial role in reducing consumption. Even a few percentage points of fuel savings translate into millions of pounds annually for long-haul operators. Additionally, noise reduction allows airlines to operate more freely at airports with strict curfews. Rolls-Royce’s comprehensive TotalCare® service packages also give airlines predictable maintenance costs, which is vital for financial planning.

Lessons Learned and Industry Response

The durability issues faced by the Trent 1000 demonstrated the importance of rapid feedback between operators, regulators, and manufacturers. Rolls-Royce invested heavily in communication channels and global support teams, working closely with airlines to implement fixes. The industry as a whole has learned from this, reinforcing the need for ongoing monitoring of engine health through digital analytics and predictive maintenance tools.

The Trent 7000: A Close Relative

While the Trent 1000 engine dominates discussions due to its widespread use on the Boeing 787, the Trent 7000 engine deserves equal recognition. Developed as the exclusive powerplant for the Airbus A330neo, the Trent 7000 borrows extensively from the Trent 1000 TEN while incorporating improvements from the Trent XWB.

With a thrust range of 68,000 to 72,000 pounds, the Trent 7000 balances high efficiency with the flexibility required for medium to long-haul flights. Its design ensures a 10 per cent reduction in fuel burn compared with older A330 engines and halves perceived noise. Together, the Trent 1000 and Trent 7000 engines showcase Rolls-Royce’s approach of applying cross-programme innovations to maximise value for both manufacturers and airlines.

The Future of the Trent 1000 and 7000

Sustainability is the key driver for the next era of aviation. Rolls-Royce continues to adapt both the Trent 1000 and Trent 7000 to operate with sustainable aviation fuels (SAF), with testing already confirming compatibility with 100 per cent SAF blends. This capability will allow airlines to significantly reduce carbon emissions without altering infrastructure or aircraft design.

Additionally, digital twin technology is being applied to monitor Trent engines in real time, predicting potential issues before they occur. These advancements aim to extend service intervals, improve reliability, and reduce lifecycle costs.

Passenger Experience and Airline Benefits

From the passenger’s perspective, the Trent 1000 engine contributes to a quieter cabin and smoother flight experience. For airlines, the benefits extend beyond efficiency: reduced downtime, extended service intervals, and long-term support all contribute to operational stability. The lessons learned from the Trent 1000 are directly shaping the success of the Trent 7000, ensuring fewer issues at entry into service and greater reliability across the Airbus A330neo fleet.

Looking Ahead: Innovation Beyond the Trent Series

While the Trent 1000 and Trent 7000 engines are central to current wide-body operations, Rolls-Royce is also preparing for the next generation of propulsion. UltraFan®, the company’s future concept, aims for at least 25 per cent better fuel efficiency compared with the first Trent engine. Innovations from the Trent 1000 and Trent 7000, including advanced materials and digital monitoring, are feeding directly into this new programme.

Conclusion

The Trent 1000 engine remains a vital part of the global aviation landscape. Despite early operational challenges, Rolls-Royce’s commitment to improvement has ensured that airlines continue to benefit from its efficiency and reliability. Alongside the Trent 7000 engine, it symbolises the adaptability and forward-looking spirit of the Trent family. As sustainability, digital monitoring, and cost reduction continue to define the future of aviation, the Trent 1000 stands as both a lesson in resilience and a benchmark for innovation.